Spare parts management system

An efficient spare parts management system (SPMS) is critical for network maintenance, repairs and operations (MRO) in the telecom industry that is both asset intensive and owner of costly assets. However, because components failure is rather unpredictable, it is very difficult if not impossible to coordinate the demand for spare parts with the supply of spare parts.

Thus, too often, operators have to choose between missing spare parts and carrying an excessive inventory.

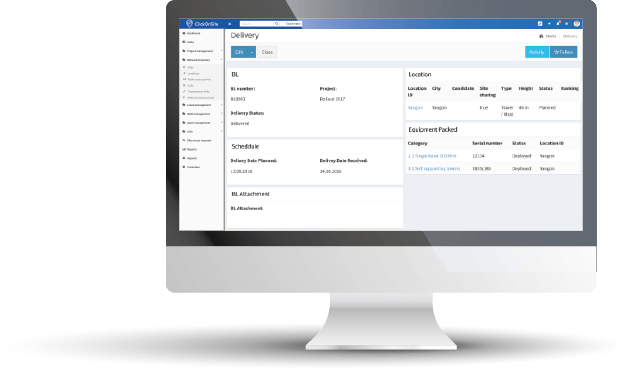

The first objective of ClickOnSite SPMS features is to give every actor of the maintenance process complete transparency of the available stock and therefore of the possible completion of current maintenance tasks. Secondly, ClickOnSite helps operators to optimize their stock replenishment and ensures the availability of spares for maintenance if and when required.

Thirdly, it gives them better control over their reverse logistic activities and allows instant data analysis of material returned from sites.

Key benefits

Challenges

Therefore the challenge for a spare part manager is to support maximum spare part availability with minimum stock.

Transactions

It is worth knowing that you have spare parts, it is even better to know where they are. Therefore, ClickOnSite enables logistics staff and field technicians to record any transaction they make to give visibility on stock transfers but also across the entire service organization. All transactions can be tracked online.

At the warehouse, the possibility to import from an XL sheet, scan bar codes, or simply enter references from the spare catalogue makes it quick and easy. It is as simple for field technicians who might use their ClickOnSite PDA or even their smartphone and the COS application to record retrieving or placing a spare from/to equipment.

Stock

Spare parts are a great asset to your operation provided that you can find them and use them. Instead of ordering a new spare every time you need one, make sure you do not have it somewhere in stock. Where it might be complicated to make a visual check it becomes very easy by searching online with ClickOnSite no matter if you have one or several storage spaces, including the cars of your field technicians or even your contractors.

Return material authorization

Today, for many of you, RMA is a black box. Are the faulty cards returned to the OEM? Are they returned from the OEM after repair or exchange? Do we benefit from the equipment guaranty? Do I actually pay the right price? Those are many questions difficult-to-answer questions because of a lack of information and control.

ClickOnSite will help you to record RMA requests and monitor each RMA item until its return. Moreover, it collects date and delays along the RMA process keeping track of your service level agreements (SLA).

Failure report

Radio vendors might try to enforce the use of their own failure report. ClickOnSite took this constraint into account and allows field technicians to simply attach the OEM report for faulty equipment. Nevertheless, you might also decide that every OEM should use the

ClickOnSite standard and detailed failure report that is synchronized with your RMA process. Likewise, you keep a complete history of failures for thinner analysis of downtime origin and extraordinary costs.

Functionality summary

Spare parts management system

- Identification of spare parts

- Inventory (Total stock control)

- Multi-location stock management (Spms stock, contractors, BSC, etc.)

- Transaction details

- Spare part tracking

- Assisted replenishment

- Failure reports

- RMA & SLA monitoring

- Replenishment & automatic ordering

- Android API