How to improve your corrective maintenance process? How can simple tools help you? Our ITD Research partner clarifies the issue for you.

©Photo: Orange Group/Christian Gesbert

Definition

Corrective maintenance is carried out after the failure of service or equipment and is intended to put the site equipment in a nominal state in which the site can perform its required functions. In response to equipment failure, corrective maintenance tasks identify the equipment failure and rectify the failure so that the equipment can be reinstated and the facility service on the site restored.

Corrective Maintenance can be also defined as unscheduled repairs on reported failures, or replacement of parts to restore equipment to working condition. It is also known as Repair and Replacement, Run-to-Failure, Failure-Based Maintenance, Fire-Fighting Maintenance, or Breakdown Maintenance. Corrective Maintenance activities are carried out only after an equipment breakdown. The reason is that it is complicated and difficult to predict stochastic and unforeseen equipment failures and breakdowns. It may be a good strategy where the failure rate of equipment is normal and the cost of breakdown is low. In the long term, however, it is more expensive than Preventive Maintenance because, for example, a sudden breakdown in the case of tower equipment creates haphazard troubleshooting scenarios and unplanned interruptions of services operations. Therefore, while Corrective Maintenance can be useful, it is usually an expensive option when used in isolation.

The specific metrics of the corrective maintenance

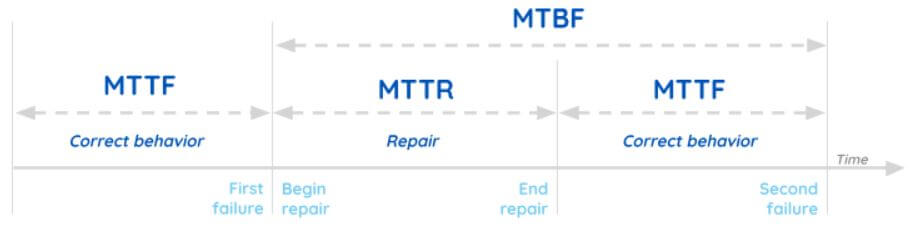

In order to improve the process of corrective maintenance, a number of important metrics have been proposed (cf. figure below):

- Mean Time To Failure (MTTF) is a metric that describes the expected time to failure for a non-repairable system.

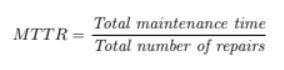

- Mean Time To Repair (MTTR) is a maintenance metric that measures the average time required to troubleshoot and repair failed equipment. MTTR gives organizations a more accurate analysis of how well their teams are responding to repairs and equipment problems. It is computed as follows:

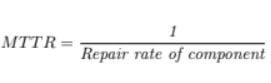

If the repair rates of items are constant, the MTTR can be also computed by the equation:

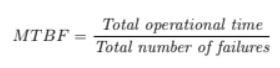

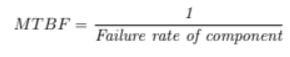

- The Mean Time Between Failures (MTBF) is a metric that represents the average time between each failure. Its counterpart is the MTTR. It is computed as follows:

If the failure rates of items are constant, the MTTR can be also computed by the equation :

The two different types of corrective maintenance

Corrective maintenance can be divided into two categories.

Deferred corrective maintenance

This usually refers to non-critical equipment having little influence on service. Such maintenance activities can be conducted together at a planned period afterward without worrying about their negative impacts on the service continuity. This can also be due to a limited budget, time, or staff.

Immediate corrective maintenance

This refers to that of critical equipment significantly affecting on-site operation. These failures are considered critical and corrective actions are needed without delay. It is thus also called unplanned corrective maintenance.

Manage your corrective maintenance with ClickOnSite

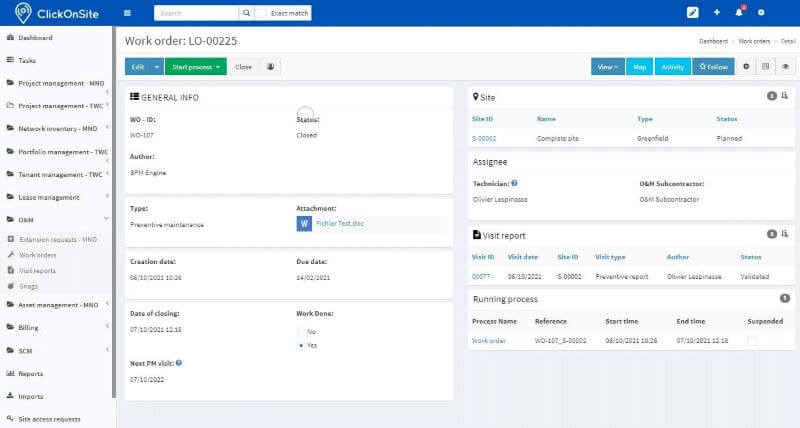

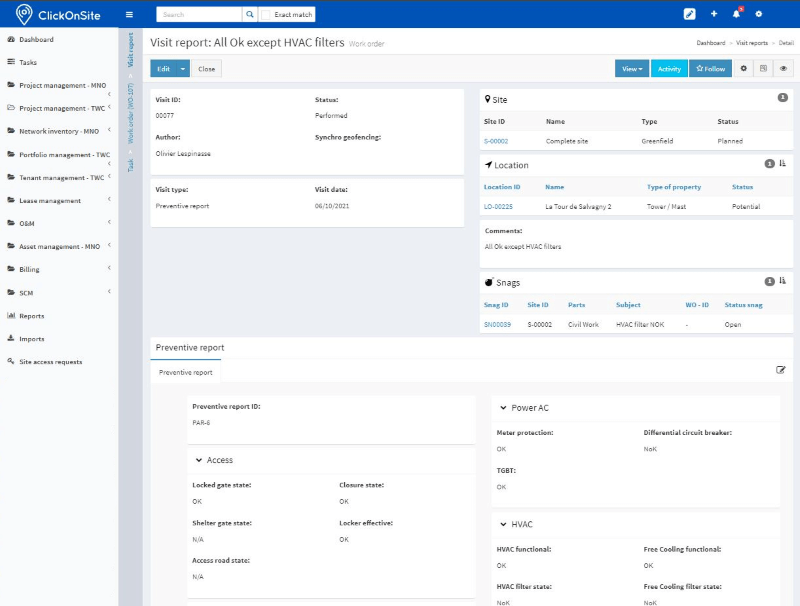

For each corrective maintenance action, ClickOnSite provides a “visit report” which shows the service dates of all the corrective maintenance visits for sites. Moreover, when specific conditions are met, a work order for an inspection is triggered. The “visit report” and the “work order” are composed of (cf. ClickOnSite screenshots below):

- WO – ID number: The maintenance task identifier

- Site ID: which indicated the location of maintenance action

- O&M Subcontractor

- O&M manager

- Type of maintenance action

- The creation and due date

- The date of acknowledgment

- Work complete

- Work performed

- End of work (forecasted)

- Start of work (planned)

- Coordinates

- Work to do

- Next preventive visit in

- Next preventive maintenance visit

Example of ClickOnSite work order

ClickOnSite provides an easy way for teams to log and note corrective maintenance issues by using the item “Assignee” which is composed of “Technician” and “O&M subcontractor”. It also allows maintenance to be planned for a time when the site equipment is scheduled to be down to make those needed repairs and restore the site back to normal operating conditions. The repair work can be described by the items “Work performed”, “Picture work done”, “Start of work”, and “End of work”. ClickOnSite also makes it much faster and easier for the maintenance teams to quickly follow up on the reported failures of service interruption. This way, technicians can then coordinate with production to schedule a time to complete the work.

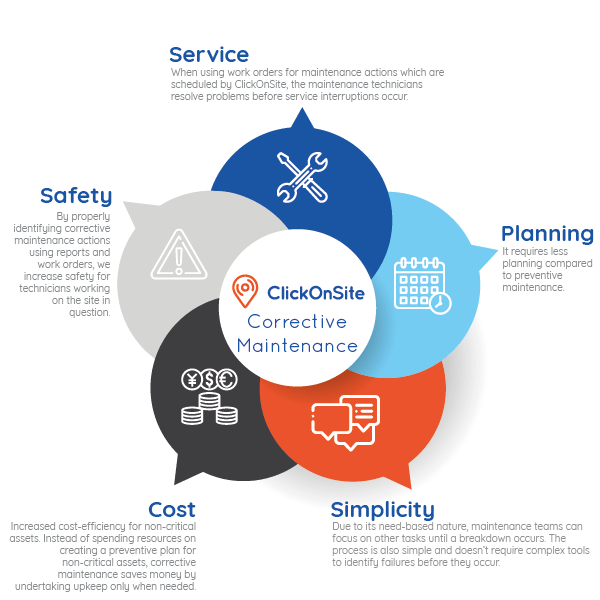

Benefits of ClickOnSite corrective maintenance

ClickOnSite provides the following benefits when used for corrective maintenance:

Coming soon: our fourth chapter is dedicated to predictive maintenance.

References:

[1] European norm EN-13306 AFNOR. Maintenance Terminology. 2018.

[2] Kojchen K. and Monchy F. Maintenance: outils, méthodes et organisations efficientes.

Dunod, 2019.

[3] Ran Y., Zhou X., and Lin P. et al. A survey of predictive maintenance: Systems,

purposes, and approaches. IEEE Communication Surveys and Tutorials, 2019.

[4] R. Louhichi, Elaboration of an economic model for decision aid optimizing the

maintenance strategy of transport systems. Thèse Université de Technologie de Compiègne,

2021.

[5] Bouami D. Le grand livre de la maintenance. Afnor Éditions, 2019.

Mohamed SALLAK

Ph.D. and Associate Professor/HRD

at Heudiasyc Laboratory

in Technology University

of Compiègne (FRANCE)

More information on his background,

research fields, projects, and other publications here.